Table of Contents

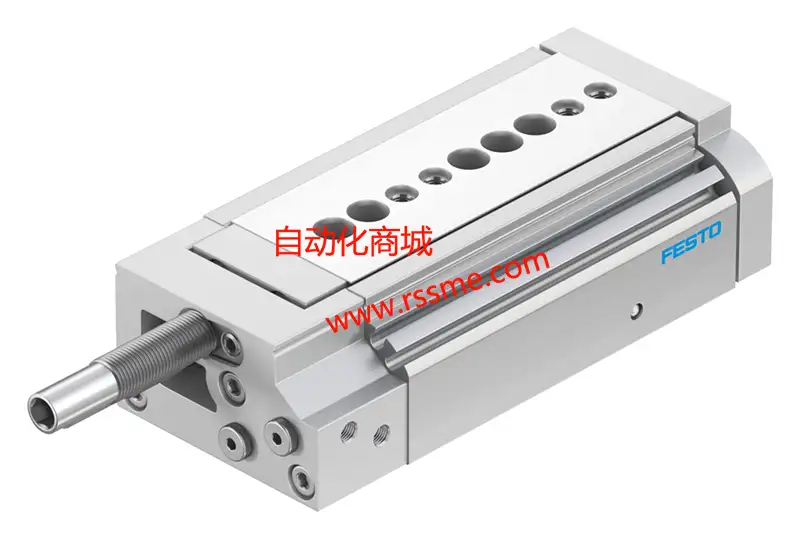

DGSL-12-40-Y3A is a small slide launched by Festo. It is designed according to ISO 6432 standard and has the following core advantages:

Compactness and installation flexibility

The circular design is suitable for installation in a small space and supports any assembly position

Symmetrical interface design simplifies the installation process and does not require additional buffering elements (integrated progressive hydraulic buffer)

High-precision motion control

Repeatability is up to ±0.01 mm, and the ball bearing cage guide ensures smooth operation under load

Double-acting drive mode, working pressure range 1–8 bar, maximum speed 0.8 m/s

Intelligent detection and adjustment capabilities

Built-in proximity sensor interface for real-time position sensing

Adjustable end position range: 25.5 mm at the rear (fine adjustment of the stroke by removing the stopper)

Technical parameters

| Category | Parameters |

|---|---|

| Stroke length | 40 mm |

| Piston diameter | 16mm |

| Maximum speed | 0.8m/s |

| Compressed medium | Compressed air, in accordance with ISO 8573-1:2010 [7:4:4] |

| Ambient temperature | 0-60℃ |

| Cushioning method | Progressive hydraulic cushioning |

| Corrosion resistance level CRC | No corrosion resistance |

Maintenance recommendations

Stainless steel version is recommended for corrosive environments

DGSL-12-80-Y3A can be considered for long stroke requirements

Proximity switches (such as SMT-8M-A-PS-24V) are required for position detection

Compressed air in accordance with ISO 8573-1:2010 [7:4:4] is recommended

Ensure that the system can be fully flushed during installation to avoid accumulation of chloride ions

Lubrication must be maintained continuously after lubrication

Application scenarios

Typical scenarios

Precision assembly, material handling, automotive manufacturing (such as the hot press hemming mechanism modification case of Yanfeng Jinqiao)

Semiconductor/life science equipment (relying on high cleanliness certification)

Usage recommendations

Buffer adjustment: If the load is less than 1 kg, it can be replaced with a small hydraulic buffer (such as DYSW-4-6) to increase life

Anti-corrosion design: Avoid stagnant areas and ensure that the fluid is completely discharged; stainless steel models are recommended for highly corrosive environments

Lubrication management: Once the lubricating compressed air is enabled, it must be maintained throughout the process, otherwise the seal (HNBR material) will be damaged

DGSL-12 series differentiation

| Parameters | DGSL-12-40-Y3A | DGSL-12-80-Y3A | DGSL-12-100-Y3A |

|---|---|---|---|

| Stroke | 40 mm | 80 mm | 100 mm |

| Maximum thrust | 104 N (6 bar) | 104 N (6 bar) | 98 N (6 bar) |

| Overall length | 165 mm | 205 mm | 225 mm |

| Torque resistance | 0.12 Nm | 0.14 Nm | 0.10 Nm |

| Applicable scenarios | Precision fine-tuning | Medium-stroke handling | Long-stroke positioning |

Product display

Festo small slide DGSL-12-40-Y3A

Festo small slide DGSL-12-40-Y3A

Contact Us

WeChat ID:rssme_com

在线留言